Table of Contents

ToggleIntroduction

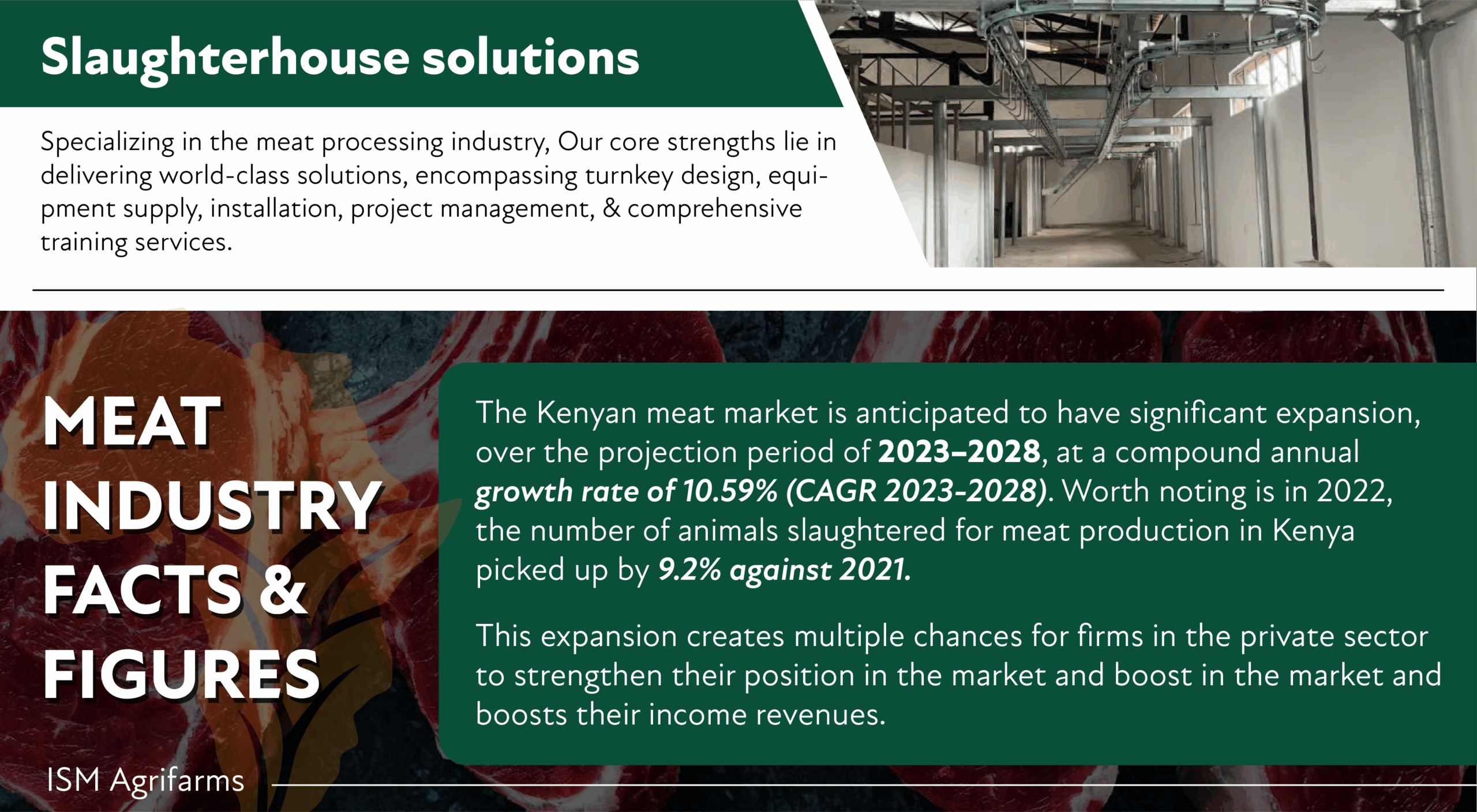

The global demand for high-quality meat continues to rise and producers must do more than just meet local demand – they must meet the world’s standards. That means investing in smarter, cleaner, and more sustainable slaughterhouse operations. At ISM Agrifarms, we design future-ready facilities that combine efficiency, sustainability, compliance, and innovation.

A remarkable example of our approach to modern slaughterhouse innovation is the Laikipia Slaughterhouse project, designed to meet the growing demand for export-quality meat. This state-of-the-art facility processes 100 cows and 300 goats daily. The project does not just show proof of concept, it is a tangible demonstration of how modern engineering can optimize both capacity and product quality.

Essential Upgrades for Export Compliance

Smart Facility Design

· Zonal Isolation – There are dedicated areas for each processing phase (lairage (animal housing), slaughter, chilling and dispatch to reduce contamination risk.

· Unidirectional Workflow – A straight, logical movement of animals and meat minimizes backtracking and keeps hygiene intact.

· UV Sterilization & Antimicrobial Surfaces – These maintain strict sanitary standards, ensuring meat safety from floor to ceiling.

Technology and Automation

- Robotic Processing Lines: This helps by reducing human error, improves precision, and scale production.

- IoT Monitoring Systems: There is real-time control of temperature, humidity, and hygiene metrics to boost compliance.

- Blockchain Traceability: Every cut of meat from farm to fork is tracked, building buyer trust.

Cold Chain Management

- Blast chillers and solar-powered cold storage for freshness retention

- Refrigerated transport to maintain quality through export logistics

Sustainability in Action

- Solar Energy: Having your slaughterhouse run significantly on solar, reduces carbon footprint, cuts down on operational expenses and is a much more reliable source of energy.

- Biogas Digesters: Animal waste is converted into renewable energy fueling power and heat, creating a closed-loop system.

- Waste Utilization: Byproducts like blood and bone are transformed into fertilizer and pet food.

- Water Recycling: Cuts consumption and aligns with global environmental protocols.

Benefits of Modernization

Investing in such modern slaughterhouse infrastructure is a smart investment and provides multiple benefits. Some of these benefits are;

- Boosts long-term profitability through reduced waste

- Shortens time to market with faster processing

- Reduces operational costs with energy-efficient systems

- Improves buyer confidence with traceable, hygienic products

- Opens new markets by meeting international certification standards

- Boosts productivity and reduces labor dependency

- Enhances your brand image and compliance

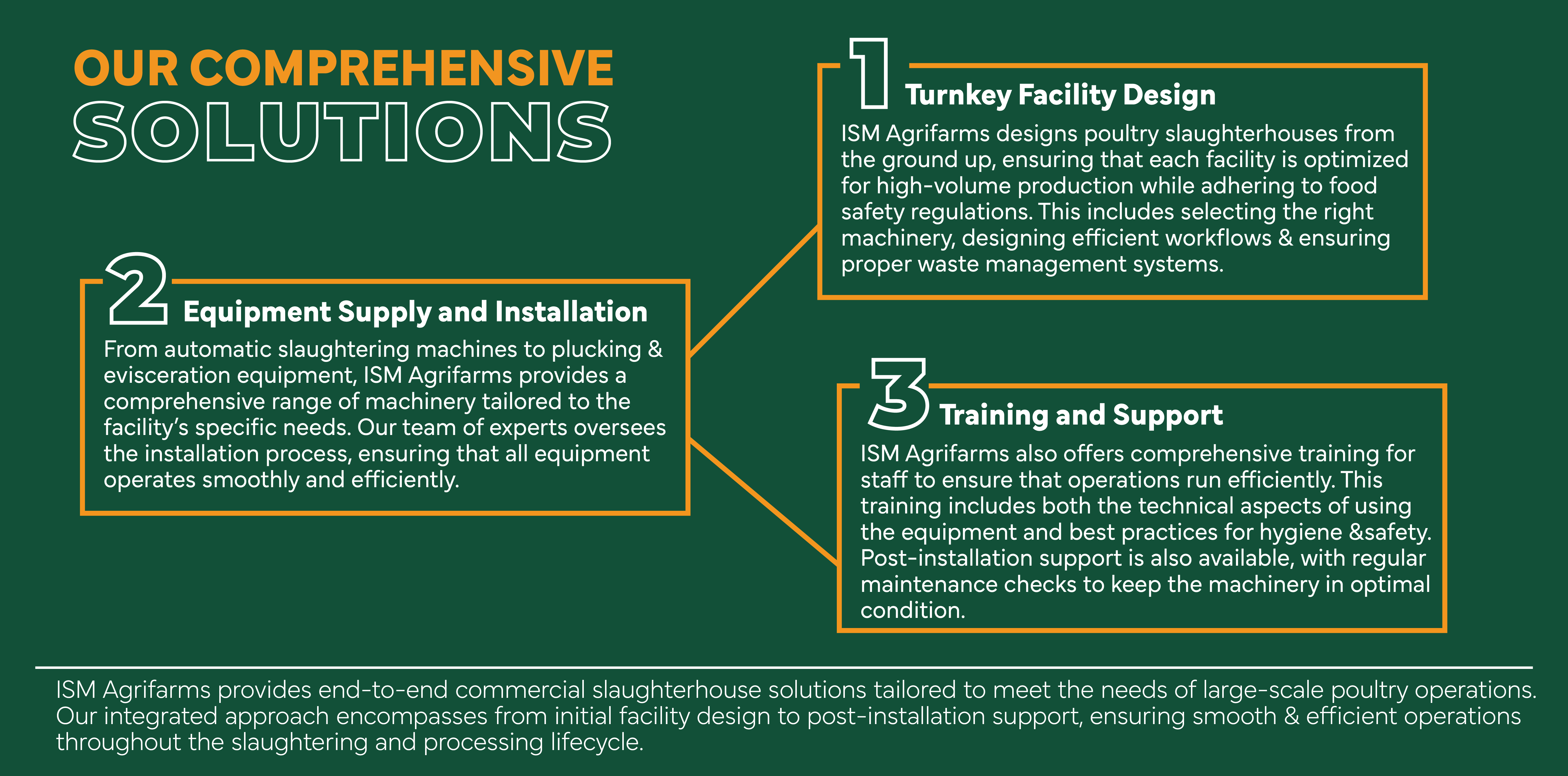

How can ISM Agrifarms help?